When it comes to cementing operations in the oil and gas industry, plug cement heads are essential components. These specialized tools allow operators to control the flow of cement into the wellbore during cementing operations, ensuring that the cement is delivered precisely where it is needed to create a secure and reliable cement sheath. There are several types of plug cement heads available on the market, each with its unique features and benefits. In this article, we will explore the most common types of plug cement heads used in the oil and gas industry.

Single-Plug Cement Head

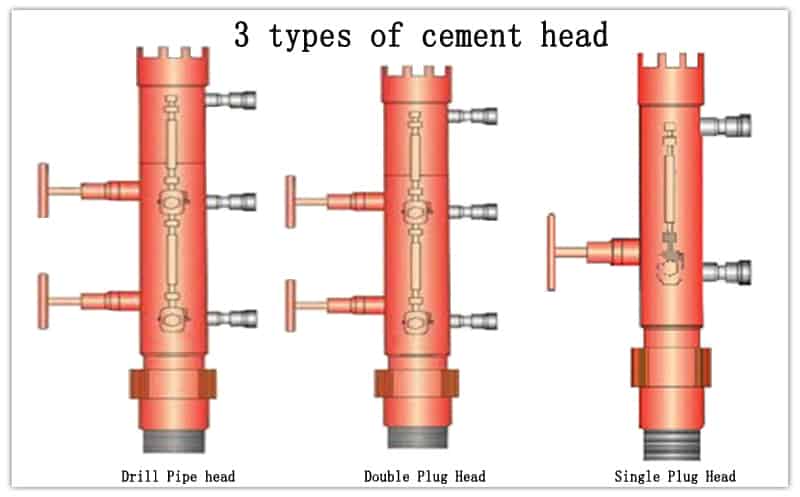

A single-plug cement head is a basic type of cement head that is used to introduce cement slurry into the wellbore. This type of cement head typically features a single, large-diameter valve that allows the cement slurry to be pumped into the wellbore. Once the desired volume of cement has been pumped, a single rubber plug is released from the cement head, which separates the cement from the drilling mud and prevents backflow of fluids. Single-plug cement heads are commonly used in less complex cementing operations.

Double-Plug Cement Head

A double-plug cement head, as the name suggests, features two rubber plugs that are used to separate the cement from the drilling mud. This type of cement head is designed for more complex cementing operations, where multiple cement slurry stages are required. The double-plug cement head is typically used to allow for the introduction of a displacement fluid between two cement stages, ensuring that there is no mixing between the two stages of cement.

Drill Pipe Cement Head

A drill pipe cement head is a specialized type of cement head that is designed to allow the cement slurry to be pumped through the drill pipe. This type of cement head is particularly useful when the wellbore is not accessible with a regular single or double-plug cement head. Drill pipe cement heads are commonly used in deepwater drilling operations, where the cement must be pumped through the drill pipe and out the drill bit.

Non-Rotating Cement Head

A non-rotating cement head is designed to prevent the cement from rotating during the cementing operation. This type of cement head is particularly useful in situations where the cement needs to be delivered precisely to a specific area of the wellbore. The non-rotating cement head helps to prevent the cement from being displaced or disturbed during the pumping process.

Bottom Plug Cement Head

A bottom plug cement head is used to introduce the final stage of cement into the wellbore. This type of cement head features a specialized bottom plug that is designed to seal off the bottom of the wellbore, ensuring that the final stage of cement is delivered precisely where it is needed. Bottom plug cement heads are commonly used in well completion operations, where the final stage of cement is critical to the well’s long-term stability.

Conclusion

In conclusion, plug cement heads are critical components in the cementing process for oil and gas wells. By understanding the different types of plug cement heads available, manufacturers can choose the appropriate equipment for their specific cementing needs. Whether it’s a single-plug or double-plug cement head for less complex operations, a drill pipe cement head for deepwater drilling, or a non-rotating or bottom plug cement head for more complex operations, selecting the right plug cement head can help ensure successful and reliable cementing operations.